| Throughput: | up to 1000 parts/hour |

| Placement Accuracy: | ± .02mm |

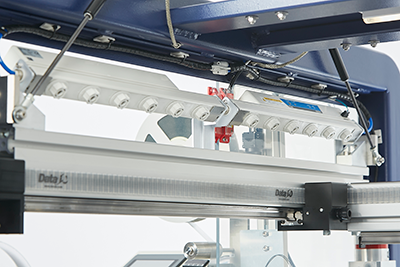

| Pick-and-Place Method: | - Single-probe stepper actuated z-motion with

- Servo-drive theta (rotation axis)

|

| Component Range: | 2mm x 3mm to 42.5mm x 42.5mm |

| Probe Stroke: | 50 mm (max) |

| Alignment: | Upward looking camera |

| System Software: | TaskLink for Windows, Data Management Software (DMS), AH700, Windows 10 |

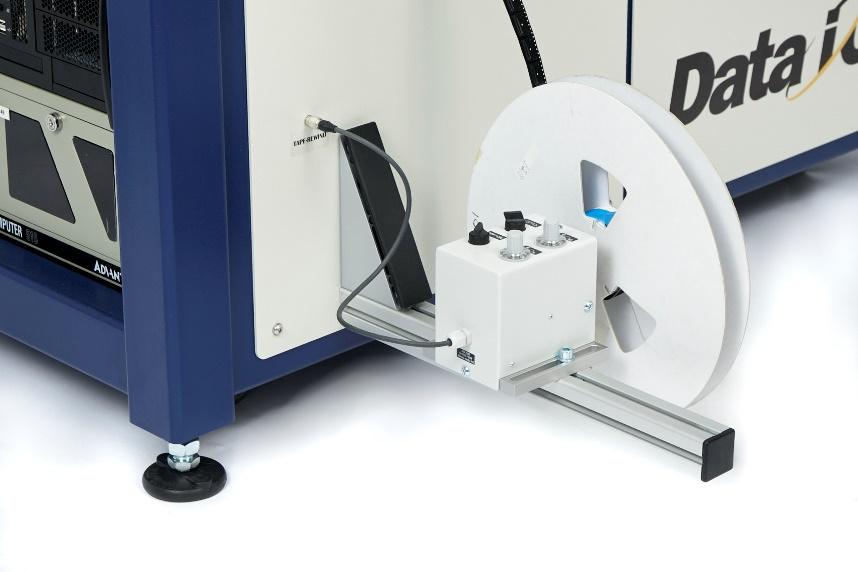

| Tape Input: | 8mm – 56mm |

| Tape Output: | 8 mm – 44mm (adjustable) |

| Dual Tray feeder Input/Output: | Supports up to 20 JEDEC Trays |

| Manual Tray: | Available without any special tooling |

| Tube Input and Output: | Available with special tooling |