- Home

- Products

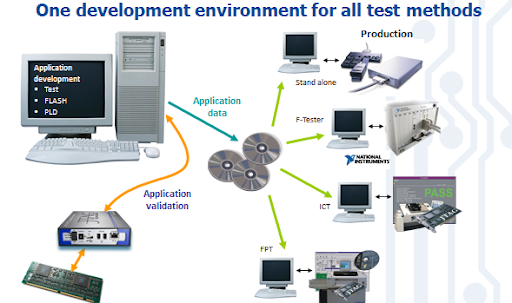

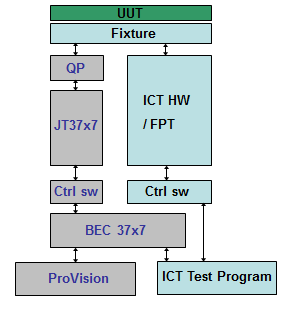

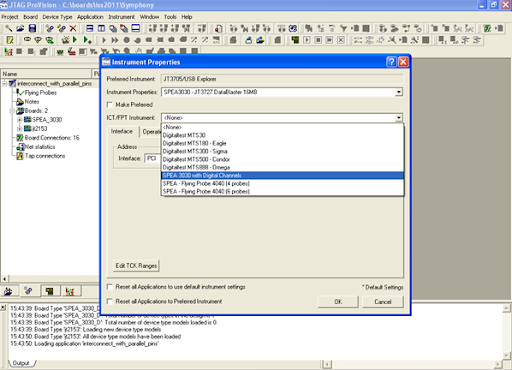

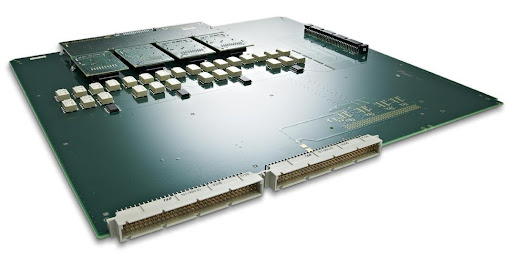

- PCBA Testing Solutions

- PCBA Assembly & Inspection Solutions

- X-ray Inspection System

- PCB Depanelling System

- 3D AOI/3D SPI/ 3DAXI/ 2D AOI System

- BGA Rework Station

- PCBA/ Stencil Cleaning System

- PCBA Coating Systems

- Traceability Solution

- Board Handling System

- Dry Cabinet

- Laser Marking Systems

- Soldering Stations

- Fineplacer BGA Re-work Station

- Robotics and Automation

- Quality & Reliability Solutions

- Semiconductor Testing Solution

- Core Business

- About Us

- Services

- Enquiry

- Contact Us