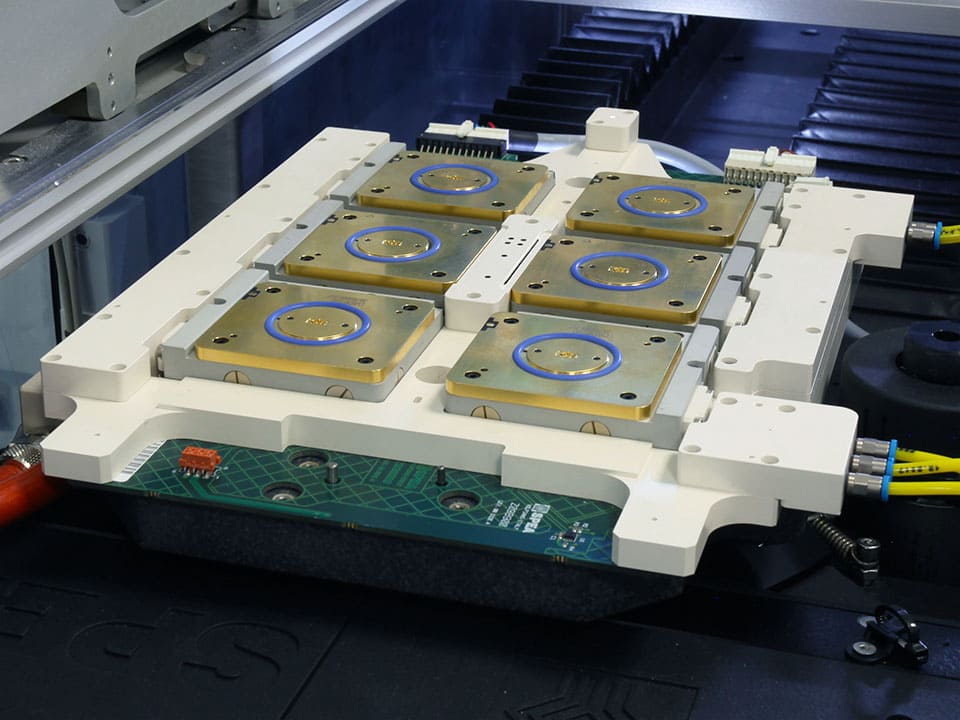

KGD Test Units

SPEA KGD test units fulfill static and dynamic test requirements of low- and high-power devices at KGD level. They perform device contacting, precise parametric testing, optical test, temperature conditioning. Combined with SPEA test handlers and testers, the KGD test units form complete test cells that include the automatic handling from and to the diced wafer.

Able to bring at die level the same performance and methods that are used to screen out defects in the final test phase, the KGD test units perform not only a complete DC parametric testing, but also AC testing, UIS/UIL Avalanche, RG/CG and Short Circuit testing.

In order to perform the dynamic tests that verify the device switching parameters, the test equipment is able to condition the device under test with both high current and high voltage simultaneously. To prevent any possible danger due to the high power dissipation, the test cell is equipped with a full range of protections, including overcurrent and overvoltage protection circuits, voltage monitors on output relays commands, open/short check, contact needle protection.

The test chambers are conditioned with a compressed air atmosphere, and specifically designed to suppress any electrical arcing phenomenon that would damage devices and test equipment.

Tester connection layout, sockets and contactors are designed to minimize the distance between device under test and test instrumentation, and to guarantee the lowest possible values of stray inductance along the whole signal path. The possibility of voltage overshoots during the commutation is minimized, since the possible overvoltage values are always lower than the breakdown voltage, under any circumstance.

Main features

- DC parametric testing

- AC testing

- UIS/UIL Avalanche

- RG/CG

- Short Circuit testing

- Optical and geometrical test

- Parasitic inductance <25nH along the whole connection chain including contacting

- Electrical arcing suppression

- Precise probing, with fine pitch probe alignment

- Temperature conditioning (-50 to +180°C)

- Full range of protections against overcurrent and overcurrent risk